In today’s bustling factories, speed and dependability drive every decision. While people often talk about cutting-edge robotics and smart software, it’s usually a handful of unassuming turned parts that quietly hold machines together. These everyday cylinders perform critical jobs in aerospace jets, car engines, robotic arms, circuit boards, and even surgical tools.

Behind their reliable performance sits a commitment to high-precision machining solutions that removes the tiniest slivers of metal with laser-like accuracy. This article looks at how turned parts fit into modern assembly lines, where they show up, and the role precision machining plays in boosting both usefulness and output.

Understanding the Role of Turned Parts in Industrial Assemblies

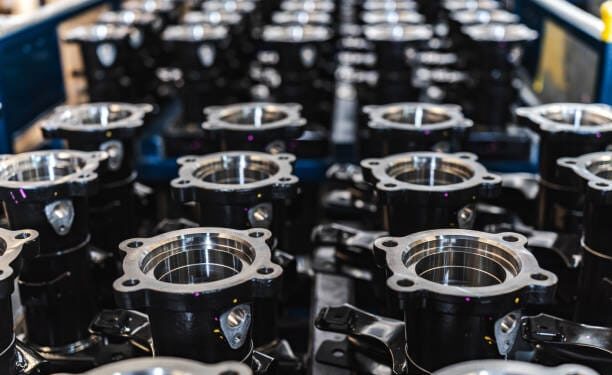

Turned parts are made on CNC lathes that spin the raw stock while a fixed tool cuts away material until the piece takes its final profile. Everyday examples include pins, shafts, bushings, bolts, and other round elements that keep moving assemblies aligned, sliding smoothly, or locked in place.

In many industrial assemblies, turned parts deliver:

- Smooth motion control

- Solid connections and joints

- Low vibration and wear

- Tighter assembly gaps

Since these pieces sit at the heart of the build, even a tiny slip in size or finish can ripple through the whole system. That is why workshops turn to high-precision machining solutions. These services promise remarkable repeatability, tight tolerances, and the knack for crafting intricate shapes in large runs.

Turned parts are also a budget-friendly choice when speed matters but quality cannot be shelved. Their consistent process and easy scale-up suit both proof-of-concept prototypes and full production runs, marrying quick turnarounds with high accuracy.

The Design Simplicity That Delivers Complex Results

The true strength of turned parts lies in their straightforward geometry. Mostly cylindrical or conical, they still carry motion, keep things lined up, and support rotating elements. Plain form aside, the stresses these components face are anything but simple.

Take a humble dowel pin in a fast-spinning machine rattling under heat and vibration. Its task is to hold position-no more, no less. Success rides on perfect cuts, smooth surfaces, and the right material choices, all supplied by high-precision machining solutions.

Today, product designers often cram lots of functions into very little space, and turn parts that fit that demand perfectly because they pack several jobs into a tiny piece. Their straightforward shape is a plus, too, since it keeps reliability high and failure risk low.

Engineers can also add coatings or surface treatments, boosting wear life, slowing rust, and raising fatigue limits. These upgrades let turned parts hold up in tough places like car engines, aircraft controls, or hospital tools.

Material Diversity and Custom Machining Capabilities

CNC turning shines because it handles many kinds of stock without extra set-ups. Shops freely choose:

- Aluminum or stainless when light weight and corrosion resistance matter

- Titanium when strength without bulk is the goal

- Brass or copper for parts that must conduct electricity

- Engineering plastics such as PTFE or PEEK to dodge chemicals and rust

With a good CNC lathe, teams adjust speeds and tools to match each material’s hardness, heat traits, and tight tolerances. That agility makes it practical to tailor parts for a strange job without slowing the line.

By the way, today’s computer-controlled lathes are perfectly willing to tackle one-off jobs like:

- Internal and external threads

- Grooves, knurls, and deep undercuts

- Axial holes, radial holes, you name it

- Stepped or tapered diameters, no sweat

That range lets engineers order components that fit their assemblies like a glove, boosting function and lifespan.

Beyond the chosen metal and tool path, finish matters. A mirror-like skin cuts drag and wear, vital in fast or heavily loaded gear. Pros nail those looks each batch, proof of solid high-precision machining.

Quality Control: The Invisible Pillar of Performance

When factories need to scale and trust every delivery, QC in turned parts is mandatory. Even tiny drift in one piece can ripple through assembly, killing schedules and field reliability.

Top suppliers of high-precision machining take quality seriously, running a set of strict checks that include:

- Measuring parts while they’re still on the machine and adjusting tool offsets on the fly

- Using Statistical Process Control, or SPC, so every decision rests on real data

- Deploying automated inspection rigs for fast, high-volume orders

- Running Coordinate Measuring Machines, or CMMs, when parts have tricky angles or curves

With this setup, every turned component hits its spec, whether the shop runs a small batch or pushes out thousands under a tight deadline. In aerospace or medical work, where failure simply can’t happen, that level of reliability is priceless.

The same focus on quality cuts back on expensive rework and waste, while boosting trust between supplier and customer. Over time, that trust paves the way for lasting partnerships that fuel fresh ideas and shared growth.

Turned Parts and the Smart Manufacturing Revolution

Although Industry 4.0 and smart manufacturing keep changing the look of the factory floor, turned parts are still at the heart of the operation. Their straightforward design and predictable machining make them a perfect fit for automated workflows, and that adaptability positions them well for high-mix, low-volume production.

New high-precision machining technology now bundles several key tools:

- CAD/CAM links that take a design straight to the shop floor

- IoT sensors that watch every step in real time

- Predictive upkeep driven by hard data on tool wear

- Lights-out runs using smart work-holding and feeding

Together, these features turn parts more quickly, cut errors, trim labor, and stay in line with JIT stock goals. When the same setup spreads through an entire plant, savings grow along with product quality.

Today, turned parts and the machines that create them stand at the crossroads of old-world skill and digital accuracy. Because of this mix, modern assemblies can still get the speed, variety, and finish today’s customers demand.

Conclusion: The Small Parts with the Biggest Impact

Turned components rarely make headlines, yet they quietly steer the success of many complex assemblies. Their plain exterior hides a blend of material science, exact engineering, and shop-floor know-how.

As designs become richer and the urge to innovate rises, turned parts will keep providing a steady backbone-if makers employ the same rigor and forward-thinking that high-precision machining now promises.

In B2B workplaces where results and reliability matter most, these unassuming parts show that smartly scaled precision can be the biggest edge you ever find.