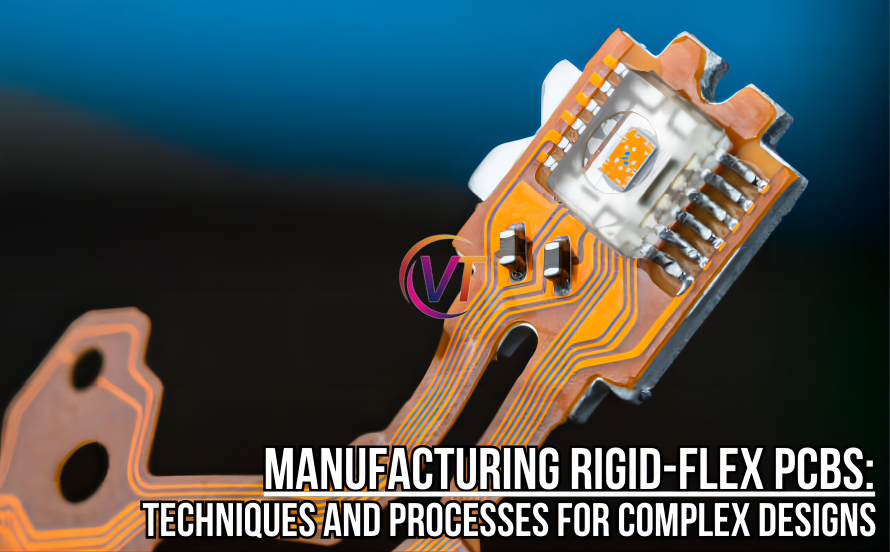

Back in the older days of modern technology, rigid printed circuit boards were popular in many electronic applications. However, these boards have the issue wherein their lack of tensile properties makes their application quite limited. The solution to that problem was the rigid-flex PCB which combined properties present in both rigid and flexible printed circuit boards – namely its stability and tensility and often came with quite complex designs.

Speaking of rigid-flex circuit boards, in this article we’ll be exploring the techniques and processes to create these technological marvels that empower the devices that we use every day.

The perks of utilizing rigid-flex PCBs

Before we move forward with discussing the techniques utilized in manufacturing a flex rigid PCB, we’ll need to understand the perks that this type of PCB can provide to the user and manufacturer. We’ll get to know what makes rigid-flex circuit boards appealing to electronic brands and manufacturers.

Listed below are some of the benefits that they can bring to you:

1. Resilient against shock or vibrations

Unlike rigid printed circuit boards, a rigid-flex PCB has the resilience to withstand shocks and vibrations since the tensile sections of the board will be the ones absorbing the force for the rest of the circuit board. As a result, these printed circuit boards are ideal for heavy mechanical setups where shocks and vibrations are frequent. These PCBs are also deceptively durable for this reason.

2. Lightweight and cost-effective electrical solutions

In comparison to their purely rigid PCB counterparts, a rigid-flex circuit board eliminates the necessity of using linkages such as connectors, cables, and wires. As a result, not only the flex rigid PCB is compact; but it is also very light making it less cumbersome if the PCB is to be transferred or integrated into an electronic device or configuration.

On top of that, its lightweight nature plays into reducing the expenses of the electronic brand or company that’s purchasing PCBs from the manufacturer.

3. Surprisingly easy and quick to assemble

It is quick for some people to assume that because a rigid-flex PCB combines the aspects of rigid and flexible circuit boards; the manufacturing process is complicated. Believe it or not, it’s the other way around as these printed circuit boards can be assembled and mass-produced quickly.

That’s because the main avenue of producing rigid-flex circuit boards is through an automated assembly line that will manage the majority of the assembly and component installation work.

4. Very reliable in many applications

Companies and manufacturers that managed to tap into the hidden potential of these PCBs will soon discover how reliable it is for use in many applications. It is no wonder why rigid-flex PCBs are considered to be one of the most reliable and flexible PCB types since they can be utilized in virtually any electronic application.

5. PCB layouts maximize space usage

Unlike rigid circuit boards, rigid-flex printed circuit boards also enjoy the benefit of being able to fit in any niche or space within an electronic configuration due to their tensile property. As a result, since it maximizes the space it is given, it can branch into device miniaturization in which the compact PCB gives way to more compact and easy-to-carry devices.

Techniques and Processes during Rigid-Flex PCB Manufacturing

Now that we’re familiar with the benefits that a rigid flex PCB can offer to your electronic brand and the manufacturer, let’s delve deeper into this discussion by talking about the techniques and processes in manufacturing these circuit boards. Listed below are the approaches and steps in making these very reliable pieces of technology:

1. Selecting the materials for the rigid and tensile parts

The first step in producing or manufacturing a rigid flex PCB is to select the materials that will be used in making the rigid and tensile sections of the circuit board. Usually, the base material tends to be Polyimide and FR-4 for the flexible and stiff parts respectively but it can vary if the buyer decides to opt for other materials instead.

Once the materials that will be used for the rigid-flex circuit board have been selected, the next phase involves procuring the materials from vendors. The manufacturer will tap into their supply network and negotiate with their suppliers for cheaper but high-quality materials and parts for your PCB.

2. Drilling in the holes

The next step in the process of making a rigid-flex PCB is the drilling of the board – usually, this process is carried out at the early stages of manufacturing, wherein the PCB is still clear and empty. The drilling process is carried out according to the specifications provided by the client in which the holes are drilled all over the printed circuit board to give way for vias and areas where components are parts will be socketed.

There’s no need to worry about human error in this step of manufacturing as this is carried out by automated machines on the assembly that will poke holes into the PCB substrate.

3. Adding the plating and circuit patterns

The next step in manufacturing a rigid-flex PCB is to install the copper plating which serves as the board’s conductive material; the copper is plated according to the client’s specifications. Once the plating is done, the next phase involves the generation of circuit patterns wherein the board’s surface is exposed to ultraviolet light.

However, before exposing the board to that light; a light-resisting film is applied on the surface of the PCB. Once UV rays come into contact with that film on the board’s surface, the pattern will be formed and the board will be ready for etching.

4. Etching and inspection

With the circuit patterns done, the next phase involves the etching process wherein extra copper is removed from the rigid-flex PCB. What’s applied on the board is an alkaline-based etchant fluid which is carefully applied as rigid-flex PCBs at this stage are still in their fragile state.

Application of the fluid is done by carefully dipping the board into the etchant fluid, however before dipping – a film of sacrificial material is added to the board so that the delicate parts won’t be damaged in the process.

Take note that once etching is done, the PCB is then inspected by technicians with the use of an automated optical inspection tool. The cameras and microscopes of this tool will check the PCB at multiple angles to see if there are errors on the surface of the PCB such as badly wired circuits, solder bridges, or poorly or excessively soldered parts.

6. The finishing touches

Before the rigid-flex PCB is prepared for the testing stage, it has to be given the proper finishing touches. A solder mask is first applied which prevents the creation and shortage of solder bridges. Once that mask is applied, the next part involves silkscreening which is labeling the parts and key components of the PCB with the use of different inks which will help the manufacturer understand the placement of the important parts of the board.

The last finish touch to be applied in this phase is the addition of the surface finish which serves as the main means of protecting the copper circuit on the board as it is vulnerable to oxidation.

7. The test before packaging

Before the PCBs are shipped to your business address, the rigid flex PCB manufacturer will conduct a series of tests to measure their electrical performance. It is also a means to detect any post-production errors such as defective parts. Usually, a flying probe test is utilized for the testing of the PCB as it is the most efficient method.

Once the board is deemed free of defects and works as intended, it is then prepared for packaging and sent off to your business address.

Read Also:- 3D Liveness Detection

Complex circuit boards made by simple means

Even though rigid-flex PCBs have some of the most complex circuit board designs, the means to create these electronic powerhouses are through the most simple methods. That’s because a significant chunk of the process is done through the use of automated machinery but with a bit of human touch.

Regardless of what method or technique is used, rigid-flex circuit boards are an electrical force to be reckoned with – powerful, reliable, and surprisingly durable in their finished form.